Barndominiums and metal buildings are popular due to their efficiency and cost-effectiveness. Prefabrication allows faster construction times, potentially lowering costs. Metal buildings use less expensive materials, like steel framing and metal siding. They are known for their durability, resistance to fire, strong winds, and pests—resulting in lower maintenance costs. Customization allows you to use them for residential spaces, workshops, and commercial storage facilities.

Barndominiums and metal buildings often face customization challenges due to their prefabrication process, which may require custom cuts or installations. Waterproofing issues are more complex in metal buildings than in traditional house framing, adding time and cost. Structural integrity may also require additional framing or reinforcements.

Prefabricated metal buildings or barndominiums have limited pre-installed options, leading to delays or customization. Installing access doors and panels may require specialized skills, potentially causing delays due to a lack of qualified workers on the construction site. In this article, we’ll explain how to incorporate access doors and panels for barndominiums and metal buildings.

Table of Contents

Challenges of Conventional Access Door and Panel Integration

Being aware of possible complications and disruptions helps you plan and execute construction projects with greater informed decision-making, which lowers unexpected costs and delays. Here are some of the challenges you will face when integrating conventional access doors and panels:

Prefabrication Headaches

The prefabrication process for barndominiums and metal structures is efficient, requiring thorough design and the construction of wall panels and roof trusses in a controlled environment. This simplified method results in faster building timelines and lower costs. However, adding access doors and panels that don’t match the prefabricated blueprint can mess with this procedure—causing delivery delays, issues with quality control, and scheduling problems. Making on-site modifications to prefabricated panels might jeopardize the structure’s integrity.

Waterproofing Concerns

Waterproofing access points in metal buildings such as pole barns and shipping container homes is a complex task that requires multi-layered protection and prevents corrosion. Builders use waterproof membranes, sealants, and flashing tapes, but improper application can lead to water accumulation, rust, and costly repairs. Specialized knowledge and experience with metal building construction techniques and materials are required, which can be more expensive than hiring contractors familiar with traditional wood framing methods.

Structural Considerations

Barndominiums and metal buildings often require additional framing or reinforcements for access doors and panels, causing complexity in the design phase. Large doors or load-bearing walls can compromise the building’s structural integrity. Engineering calculations are needed to determine the appropriate size and placement of reinforcements. Changes to prefabricated wall panels or barndominium roof trusses may be necessary, requiring clear communication with the manufacturer and potentially altering the prefabrication schedule.

Receive Quotes from Multiple Barndominium Builders & Kit Providers Near You Today (It's Free!)

Fill in this 1-minute form below and receive estimates for your project without having to find them yourself! Let them do the work.

Limited Prefabricated Options

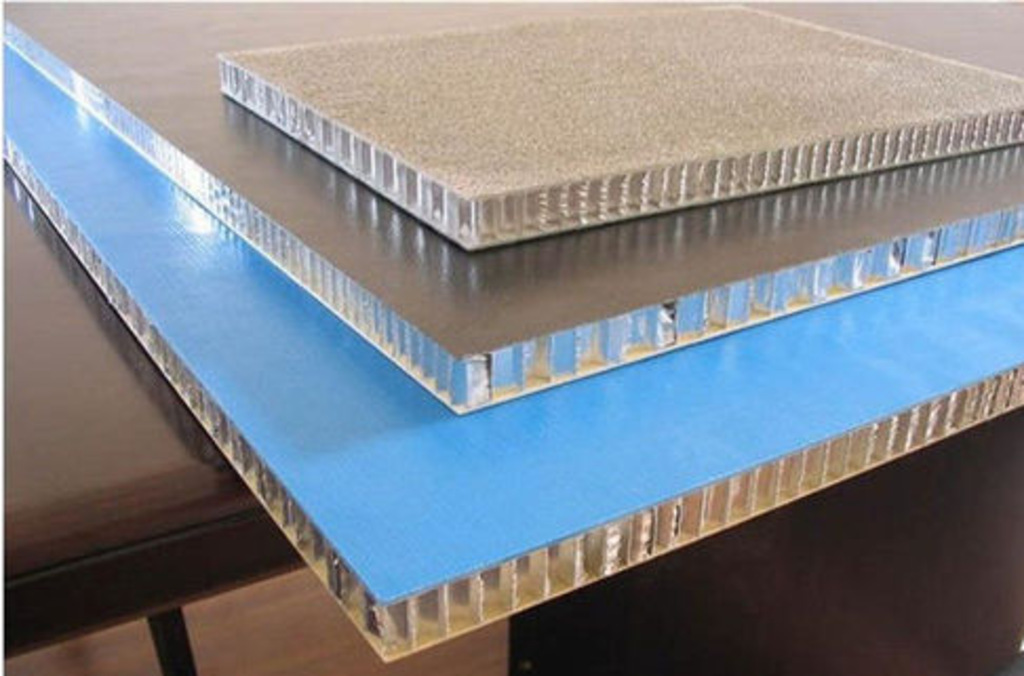

Metal building manufacturers provide pre-installed access doors and panels for barndominium and metal building projects, but these options often have limitations that can cause delays or require customization. These limitations include a restricted selection of sizes, styles, and locations, which may not perfectly suit the building’s needs. Prefabrication challenges can occur when custom access points are not seamlessly integrated, leading to production delays or modifications to prefabricated components. Balancing functionality, efficiency, and cost becomes a key challenge.

Specialized Skill Gap

Barndominiums and metal buildings, such as shouses and pole barn homes, require specialized access door and panel installation skills, which may only be available to some construction workers. A limited workforce in metal building construction techniques can make finding qualified workers for the installation phase challenging, leading to project delays and potential improper installation risks. Improper techniques can compromise the building’s waterproofing, causing leaks and structural damage, leading to costly repairs and safety hazards. Securing skilled labor ahead of time can help mitigate these risks and ensure a smooth construction process, ultimately impacting the project’s success.

Solutions for Streamlined Integration

Streamlining the integration of access doors and panels, like the BA-FRN-PF fire-rated non-insulated access panel-plaster bead flange, in barndominiums and metal buildings is crucial. It enhances functionality while considering cost-effective solutions. Here are the solutions that would give you more flexibility in size, style, and location flexibility.

Early Planning and Collaboration

Early planning is crucial for successfully integrating access doors and panels in barndominiums and metal buildings. It optimizes design, minimizes on-site modifications, and incorporates waterproofing considerations. It allows for selecting appropriate materials and techniques, ensuring a watertight seal. Early planning also facilitates coordination with manufacturers and construction crews, identifying skilled workers, preventing last-minute scrambling, and achieving cost control through accurate quotes from manufacturers.

Standardized Options

The collaboration between barndominium builders and manufacturers is crucial for implementing standardized access doors and panels in prefabricated barndominiums and metal buildings. This leads to increased efficiency, reduced delays, predictable costs, and improved quality control.

Standardized options save time and labor costs, while manufacturers benefit from streamlined production, reduced engineering costs, enhanced customer service, and competitive advantage. Builders and contractors can provide input on desired access door and panel sizes, styles, and locations, fostering innovation and a smoother construction process for barndominiums and metal buildings.

Waterproofing Expertise

Skilled waterproofing is essential for metal buildings to prevent leaks around access points. Experienced contractors use specialized materials and techniques like flashing, sealants, and membranes to anticipate potential problems and implement preventative measures. Quality control is crucial, with contractors inspecting their work at every stage. Properly waterproofed access points protect the building from water damage, reduce mold growth, and promote energy efficiency. Hiring skilled contractors upfront can save money on costly repairs and ensure structural soundness for years.

Advanced Framing Techniques

Barndominiums and metal buildings often require additional framing or reinforcements to maintain structural integrity. You can adapt prefabrication techniques to incorporate these elements without compromising off-site construction efficiency. Engineering software can design additional framing elements for specific locations, ensuring a perfect fit and eliminating on-site modifications. Reinforced wall panels can be prefabricated with integrated reinforcements around access points, while doubled-up stud framing creates a stronger frame.

Skilled Labor Considerations

Access door and panel installation in barndominiums and metal buildings require specialized skills to ensure functionality and long-term performance. Expert workers establish a waterproof seal and preserve structural integrity with metal flashing, sealants, and fasteners. Poor installation can result in expensive repairs, weakened support, and leaks. Hiring qualified workers ensures efficient installation, minimizes leaks, and protects investment in the long run.

Conclusion

Barndominiums and metal buildings can be viable but face challenges like prefabrication disruptions, waterproofing complexities, structural considerations, and limited prefab options. However, you can overcome these challenges with early planning, collaboration between builders and manufacturers, skilled labor, advanced prefabrication techniques, and a skilled installation crew. Incorporating access doors and panels in barndominiums or metal buildings should not be a disaster. Understanding these challenges can help with project completion. By applying the knowledge and solutions outlined in this article, you can confidently build a barndominum, ensuring a smooth construction experience and a functional, beautiful space.